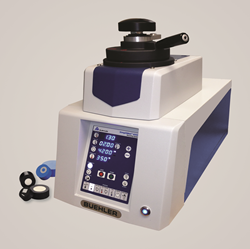

Buehler introduced on Tuesday SimpliMet 4000, an automatic, duplexing mounting press designed for use in industrial laboratories where fast reliable results are required.

Packaged within a small footprint to relieve overcrowding in the lab’s benchtops while producing more mounts, SimpliMet 4000’s single handed closure mechanism engages quickly, and makes moving to the next task a breeze. These time saving features married with rigorous accelerated lifecycle testing to 160,000 cycles deliver a press that will perform day in and day out.

The SimpliMet 4000 compression mounting system eliminates bottlenecks at the mounting stage, rapidly transforming cut samples to specimens ready for grinding and polishing. Designed to be reliable in 24/7 manufacturing environments, the SimpliMet 4000 has undergone rigorous testing to perform for long periods and last for years.

Throughput time for the lab user is improved with the SimpliMet’s fast mounting cycles and specimen duplex capabilities (where two specimens are produced simultaneously in the same mold). It is equipped with the SmartCool intelligent cooling system that optimizes cooling time while also ensuring operator safety and minimal water usage. The intuitive interface sets and stores temperature, pressure and time, thus shortening set up.

“The SimpliMet 4000 was designed to meet the needs of the most demanding labs. Reliability and speed are critical for production labs, so Buehler designed the product with these features as our primary goal, “ said Jill Dreschler, Buehler’s product manager. “Our customers demand mounting equipment that is not only efficient and durable but also preserves valuable bench space – the SimpliMet4000 meets all these requirements.”